Ensuring Piping Integrity with Advanced Stress Analysis

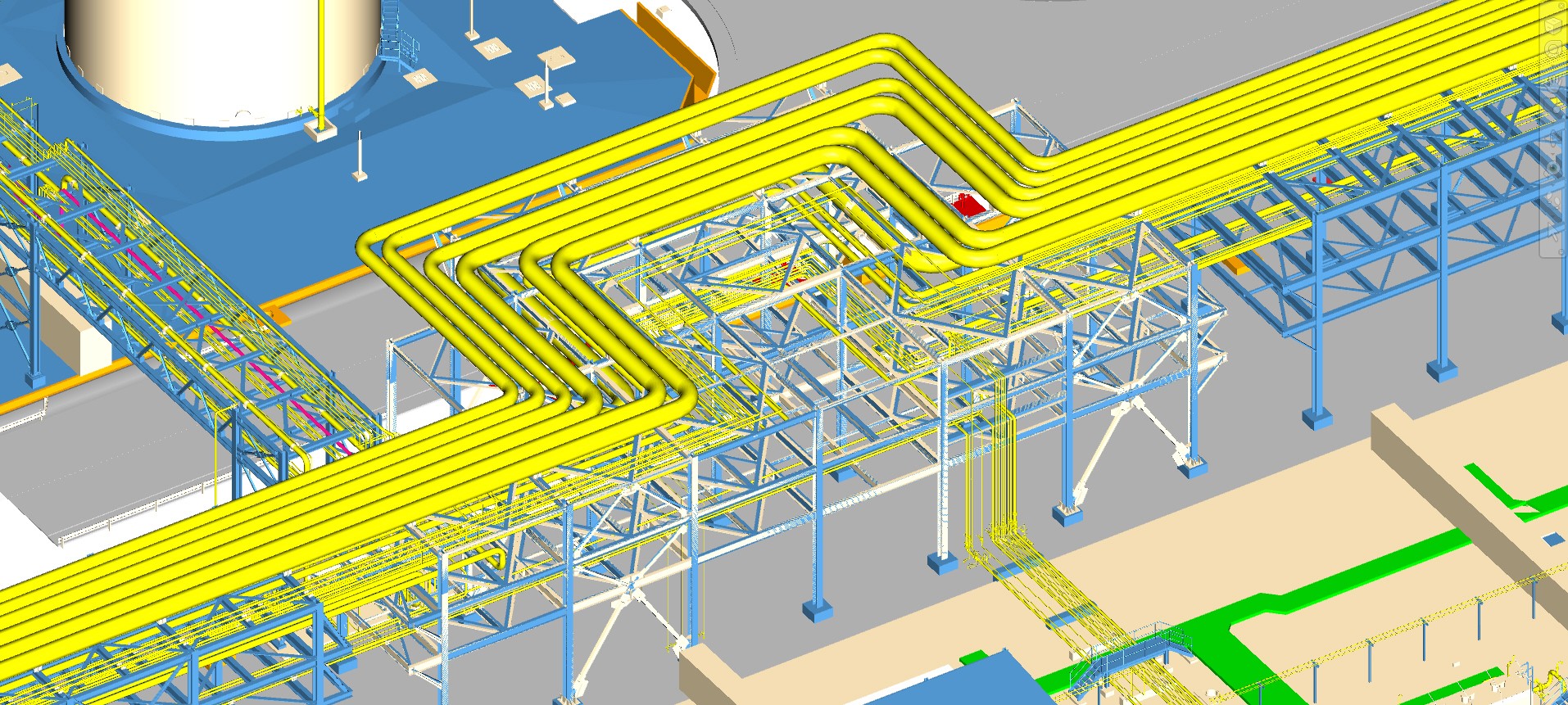

Piping stress analysis is a critical engineering process that ensures the structural integrity, flexibility, and safety of piping systems under various operating conditions. At Nikan Energy, we leverage industry-leading software like Caesar II and SAP2000 to perform detailed stress evaluations, ensuring that our clients’ piping networks comply with ASME B31.3, B31.1, API 610, and other international standards.

The process begins with a comprehensive load assessment, where we evaluate internal pressure, thermal expansion, external forces (wind, seismic, dead loads), and dynamic effects like water hammer or vibrations. Next, we conduct a flexibility analysis, ensuring that the piping system has adequate expansion loops, offsets, or compensators to prevent excessive stress on pipe connections, supports, and equipment nozzles.

Once flexibility is addressed, we proceed with support optimization, selecting and designing the appropriate rigid supports, spring hangers, guides, anchors, and sliding supports to control displacement and distribute loads efficiently. We also perform a sustained and occasional load analysis, verifying that the system can withstand continuous operational loads, as well as occasional loads such as seismic events, slug flow, and startup/shutdown transients.

How Nikan Energy Helps You with Piping Stress Analysis

✅ Prevent Pipe Failures & Leaks – Ensuring that stresses remain within allowable limits to avoid fatigue, creep, and cracking.

✅ Optimized Pipe Routing & Support Design – Reducing excessive loads on equipment nozzles, flanges, and structural steel.

✅ Compliance with International Codes – Guaranteeing adherence to ASME, API, and ANSI standards for regulatory approvals.

✅ Minimized Risk of Vibration & Fatigue Failure – Identifying and mitigating resonance, transient shocks, and cyclic loading issues.

✅ Efficient Cost & Material Optimization – Eliminating unnecessary expansion loops, oversized supports, and excessive reinforcement, saving costs while maintaining reliability.

At Nikan Energy, we don’t just run stress simulations—we engineer confidence by delivering clash-free, optimized, and structurally sound piping systems that perform safely and efficiently in the harshest environments. Let’s build piping systems that last—partner with us today! 🚀